Industrial

Product Services

- Mineral / Packaged Drinking Water Plants

- Automatic Filling & Packing Machineries

- Waste & Effulent Water Treatment

- Industrial RO Spares & Accessories

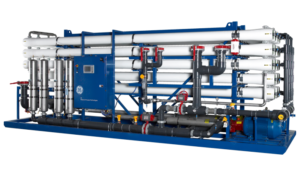

PACKAGED DRINKING WATER / MINERAL WATER RO SYSTEMS:

We are engaged in manufacturing and supplying a wide range of premium quality Packaged Drinking Water (Bottling Water) & Mineral Water Plant. These are ideal for solving drinking water problem and to meet various industrial requirements. Manufactured using high quality raw material, these are easy to install and highly efficient. They are offered at affordable prices.

6000 LPH Plant

1. Economic

2. Features:

3. High efficiency

4. Resistant to various bad wea

5. Easy to install

Mineral Water / Packaged Drinking Water Project consists of the following:

Water Source:

Water should be collected from the source which should be well protected, available easily, un-contaminated. Sources can be anything viz. Borewell water Line, Closed Ring Well, Municipal Supply Line, or another source where treatment is possible.

Water Transfer:

Water is transferred to Raw Water Storage Tanks using a proper pumping system and un-contaminating piping work. Either Submersible Pump or surface mounted Centrifugal pump can be used with good quality UPVC or CPVC or SS piping can be used for this application.

Water Treatment System:

Complete Purification system comprising of :

|

1. Raw Water feed Pump 2. Chlorine Dosing system 3. Multi Sand Media Filtration for Coarse filtration 4. Activated Carbon Filtration 5. Water Softening / Anti Scalent Treatment Process 6. Micron Cartridge Filtration (5 Micron) 7. Reverse Osmosis Filtration |

8. Purified Water Storage in Stainless Steel tank 9. Transfer Pump in stainless steel Pump 10.Micron Cartridge Filtration (1 Micron) 11.Micron Cartridge Filtration (0.2 Micron) 12.Final Purified water Storage in SS tank 13.UV Sterilization 14.Ozone Disinfection |

Water Process Description:

Pre Treatment :

Raw water is chlorinated to oxidize the organic impurities (kill bacteria and virus). This water is passed through Multi Media Sand Filter with the help of Feed pump of suitable capacity to remove suspended impurities followed by Activated Carbon Filter to remove excess chlorine (de-chlorination), odour, colour and turbidity due to colloidal suspended impurities and organic impurities.

RO System :

De chlorinated water is then dosed with Anti Scalent Solution to avoid scale formation on the membrane or passed through Softener to remove hardness. Softened water is further passed through 5-micron cartridge filter to remove micron particles to avoid clogging of the RO membrane and to improve the silt density index. Water further passed though RO Unit which is complete with High Pressure Pump, Membranes with Pressure tubes, Electrical control panel and wet panel, piping with valves and all the required accessories viz., pressure switch, solenoid valve etc. Reverse Osmosis unit will reduce the dissolved Salts up to 95% of the in feed TDS. Treated water from RO unit will be stored into SS tank.

Post Treatment :

This treated water is then passed through 0.2 micron cartridge filter before it is taken for the filling. Ozonator unit producing ozone gas is installed in series at the outlet of UV System to provide the residual effect of ozone to the water.

Water Testing Facility :

Purified Water is tested using IN HOUSE Water Testing laboratory Where Chemical and Micro Biologically Water is tested for Chemical and Micro Biological parameters. For this, a complete full fledge Water Testing CHEMICAL and MICRO BIOLOGICAL Lab is required. However, water is also tested for Toxic Substances, Pesticide and Radio-nuclear parameters in outside Bureau of Indian standards approved laboratory. (Also, see Laboratory Service…)

Laboratory Requirements :

| Chemical Lab:

Min 150 sq. ft Room / Shelves, Cup-boards (Your Scope) |

Micro-Biology Lab:

Min 150 sq. ft Room / Shelves, Cup-boards (Your Scope)

|

3000 LPH Plant 3000 LPH Plant |

4000 LPH RO 4000 LPH RO |

5000 LPH Plant 5000 LPH Plant |

10000 LPH Plant 10000 LPH Plant |

AUTOMATIC PET BOTTLE RINSE, FILL, CAP AND SEAL MACHINE:

- Machine has fully automatic Rinsing, Filling, Capping operations.

- Body Labeling with Hot Melt BOPP Labels OR PVC Shrink Labels.

- Product Hygienic and untouched by human hand.

- Bottle Fill 300 ml to 2.0 Lt in the same machine, using change parts at an extra.

Machine Capacities

Various capacity Machines are available

1. 24 Bottles/min

2. 45 Bottles/min

3. 60 Bottles/min

4. 120 Bottles/min

5. 250 Bottles per min and more

Machines are supplied with standard accessories:

- In feed Air Conveyor of SS/Acrylic body with 10 feet length along with drive.

- Out feed Conveyor of SS/Acrylic body with 30 feet length along with drive.

- Electrical panel with the machine along with timers, relays, PLC etc.

- Inspection Board mounted on out feed conveyor.

- Shrink tunnel for shrinking the labels and cap sleeves.

- One set of change parts for one size of bottles. For different sizes of bottles different change parts are required which will be sent at additional cost.

- Computerized Digital Batch & Date Coding Machine to match with machine – Ink-Jet Printer. (Optional)

AUTOMATIC PET BT CANE RINSE, FILL AND CAP MACHINE:

| This section consists of 3 units mainly 1. Jar brusher Unit 2. Jar Washer Unit – 2 nos. 3. Jar Filler Unit 4. Jar Capper Unit |

Various capacity Jar Machines are available 1. 120 Jars /hour |

PET BOTTLE/ BT JAR BLOWING MACHINE:

Water once purified is filled in PET Bottles where bottles can be blown IN HOUSE using Bottle stretch Blow Moulding Machine. This Machine requires Heavy duty Compressor with Compressor Air Dryer unit. Bottles are blown using Semi Automatic Twin Blow machine.

Blow Moulding Machines are available in following capacities:

Semi Auto – 600 Bottles or 1200 Bottles per hour and multiple of 600 BPH Fully Auto – 1200 BPH / 1800 BPH / 2400 BPH / 3600 BPH / 4500 BPH etc.

BT Jar Blow Moulding Machine capacities available in 45 – 60 JPH.

Machines are available with all the accessories viz.

• Storage Hopper and Automatic Feeder of Pet Performs

• Bottle on line Feeder on Air Conveyor

• Air Compressor/s suitable capacity

• Compressed Air Dryer & Filters

• Chiller Unit of suitable capacity

• Various capacity Hard Chrome Diamond Finish PET Bottle Moulds.

AUTOMATIC PE POUCH PACKING MACHINE :

Waste water treatment plant:

We design and install Waste Water Treatment Plants that are equipped with latest machines to carry out the biochemical purification of the waste water produced by small settlements and enterprises. The plant has requisite equipment to carry out high rate clarifies coagulation, precipitation and bio-media clarification of the waste water. Our hi-tech desalination and waste water recycling plants have become economically infeasible due to high energy consumption. We have competency in installing the adequate machines as per the requirements of different industries and the content of inorganic and organic composition in the water.

Effluent Treatment Plant:

We offer Compact Type Effluent Treatment Plants that are used to purify waste material. Used in most of the factories, our effluent treatment plant helps in solving the environmental pollution problem created by the waste material of a company without exposing the same to the environment. Our effluent treatment plants are renowned for saving energy. To keep our environment safe, we offer innovative Effluent Treatment Plants to remove the pollution effluents with economical operation and quality discharge to meet the stringent pollution control norms.

Our company is one of the leading named that offer our clients with Textile Effluent Treatment Plants. These are widely appreciated for their sturdy construction and corrosion resistance nature. This effluent treatment plant is manufactured as per the predefined industrial quality standards. It is also inspected by our tea of quality analysts before final delivery. Our effluent treatment plant is offered at reasonable prices.

SEWAGE TREATMENT PLANT:

GREEN ECOTEC SOLUTIONS offers complete solution for Sewage Water Treatment Plants and Recycle. The Sewage from the residential and commercial buildings is treated for reduction in BOD, COD & TSS in order to comply with the pollution control board standards for disposal, gardening, flushing and other non-potable purposes.

The sewage treatment plants are based on the Latest FAB (Floating Aerobic Biomedia) or SAFF (Submerged Aerobic Fixed Film) treatment followed by clarification by a tube settler. Lime is dosed in for suppression of foaming tendencies. The clarified water is then further filtered in a Multi media Sand Filter after dosing of co-agulant (alum) for removal of unsettled suspended impurities followed by Activated Carbon Filter for removal of organics. The filtered water from ACF is then chlorinated & stored in the treated water tank.

These sewage treatment plants are available in RCC constructed designs for commercial and residential buildings as well as Mild Steel FRP Lined and Fiber constructed tanks for easy installation and commissioning.

Sewage treatment systems are available from 50 M3 per day to 1000 M3/day and more…Water thus obtained can be used for gardening, flushing, car washing, etc. etc..

We are Designing, Manufacturing, Erection and Commissioning of Compact Sewage Treatment Plants of Different types of Industries, Special Economical Zones (SEZs), Industrial Complexes, Municipal Corporations, Nagar Palikas, Hotel Industries, Residential Colonies. We identify and study the possible options by which treated sewage can be recycled for Gardening, Flushing or for other Process Applications for industries. We are optimizing the size and power consumption of sewage treatment plant as possible as we can by our best knowledge.

STANDARD FEATURES:

-

No Odour Generation

-

Inside and Outer protection: epoxy paint

-

Aeration system composed by a Blower, an air supply pipe, Fine bubble diffusers and an air relief valve

-

Automatic sludge recirculation system

-

Access and inspection registers in every chamber

-

Packaged and transportable plant

-

Suitable for remote locations

-

Permanent and mobile installation

-

Designed to the required capacity

RO SPARES & TREATMENT CHEMICALS :

The Reverse Osmosis systems spares we design and fabricate are extensively used to dissolve solids from the raw water. Our range of reverse osmosis system and reverse osmosis equipment is manufactured using the membrane technology. These ROs allows the water to pass through a semi permeable of 0.0001 micron gauge that separates even the smallest of microbes, soluble or insoluble wastes and softens the hard water. Our range includes high pressure pumps, dosing pumps, reverse osmosis systems spares, industrial micron filters, pipe fittings, industrial chemicals and water treatment chemicals.

Centrifugal Feed Pump Centrifugal Feed Pump |

FRP Pressure Vessels FRP Pressure Vessels |

SS Pressure Vessels SS Pressure Vessels |

Strainer |

Distribution Strainer Distribution Strainer |

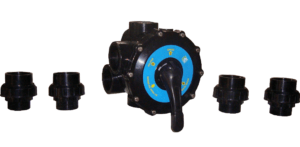

Multiport Valves Multiport Valves |

Auto Multiport Valves Auto Multiport Valves |

Sand Pebbles Sand Pebbles |

Sand Silex Sand Silex |

Activated Carbon Activated Carbon |

Softener Resin Softener Resin |

Micron Filter PP Housings Micron Filter PP Housings |

Micron SS Housings Micron SS Housings |

Micron Cartridges Micron Cartridges |

PP Pleated Filters PP Pleated Filters |

Chemical Dosing Pump Chemical Dosing Pump |

Chemical Dosing Pump (2) Chemical Dosing Pump (2) |

Chemical Dosing HDPE Tank Chemical Dosing HDPE Tank |

Pumps Pumps |

Membrane Filters Membrane Filters |

FRP Membrane Housings FRP Membrane Housings |

RO Auto Control Panel RO Auto Control Panel |

|

Flow Roto Meters Flow Roto Meters |

Squre Flow Meters Squre Flow Meters |

Pressure Gauge Pressure Gauge |

Pressure Switches Pressure Switches |

|

SS Storage Tanks SS Storage Tanks |

UV Sterilizer UV Sterilizer |

UV Sterilizer UV Sterilizer |

UV Sterilizer UV Sterilizer |

Ozonator Ozonator |

Ozonator Ozonator |

Ozonator ABS Ozonator ABS |

Membrane Housing End Cap Membrane Housing End Cap |

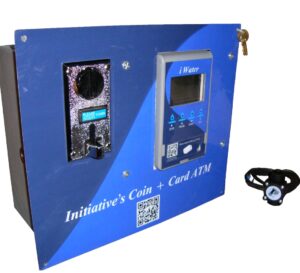

Water Vending Machine Water Vending Machine |

SS Pipelines SS Pipelines |

SS Fittings & Accessories SS Fittings & Accessories |

TREATMENT CHEMICALS:

RO Antiscalent-25kgs |

RO Antiscalent-5kgs |

Treatment Chemicals Treatment Chemicals |

PH Boosters PH Boosters |

Sodium Hypo Chlorine Sodium Hypo Chlorine |

Sodium Hydroxide Sodium Hydroxide |

Sodium Carbonate Sodium Carbonate |

Sodium Bi Carbonate |